When working with any hydraulic system, it is crucial to ensure that you have the right hydraulic hose fittings and adaptors.

This isn’t just a matter of productivity – it can also have implications for the integrity of the rest of your hydraulic system. The wrong hydraulic hose and fittings can even compromise the safety of your team.

Essentially, your choice of hydraulic hose fittings can make or break your hydraulic system.

That’s why when it comes to choosing the right fittings for your job, Gerrard Hydraulics are Perth’s preferred hydraulic hose fittings suppliers.

While there is no substitute for good one-on-one advice, we’ve put together a simple guide to help you navigate the complexity of choosing the right hydraulic hose fittings for your application.

What Happens When You Choose the Wrong Hydraulic Fitting?

Selecting the wrong hydraulic fitting may seem like a minor issue but can have far-reaching consequences for your business.

One of the most common impacts operators of hydraulic systems observe is the presence of one or more leaks. When a seal fits incorrectly or the hydraulic fitting is not designed for the type of work you have it doing, linkages can fail.

At the very least, a leak will reduce the effectiveness of your system. At worst, it can lead to the mixing of incompatible substances, which could lead to explosions or the creation of toxic byproducts.

Additionally, when working with high pressure, incorrect usage can increase the risk of hydraulic fluids being injected under the skin of operators. Pressure could also result in flying projectiles that lead to serious injury or damage to property.

Exploring Different Types of Hydraulic Hose Fittings

Hydraulic hose adaptor fittings come with a variety of specifications, based on the job they are designed to do.

Various industry standards, such as the applicable ISO for your industry, may also dictate the type of fitting you need. It is not recommended that you mix fittings from different manufacturers.

The main types of hydraulic hose fittings are:

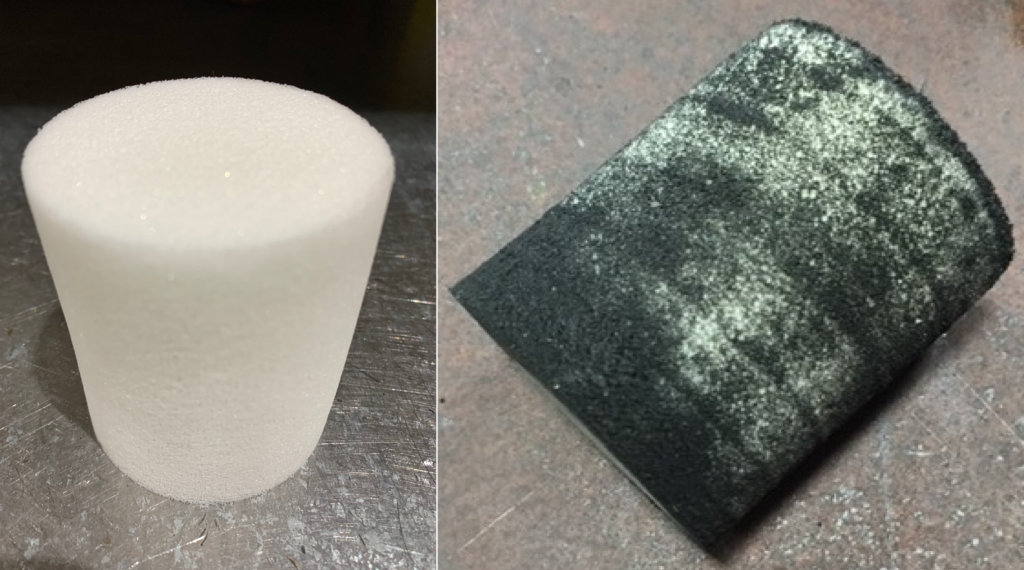

– Permanent crimp fittings – These fittings result in a permanent attachment. Using a bench-based or portable crimping machine, this fitting creates a strong, reliable connection. This type of fitting is essential for high-pressure systems.

– Field-attachable hydraulic hose connector fittings – Easy to apply out in the field, this fitting type is a convenient solution when an immediate repair is needed. It can also be reused elsewhere. However, this fitting type is prone to failure and is not suitable for high-pressure systems.

Factors to Consider: Threading, Sealing, and Compatibility

When choosing the right hydraulic hose pipe fittings for your requirements, it is also important to consider the following:

Threading – Ensure thread compatibility by always buying from the same manufacturer.

Sealing – Match the seal to the job. If using elastomeric seals, monitor your operating temperature carefully, because even one instance of over-temperature can cause seal failure.

Compatibility – Beyond simply making sure your fittings are compatible, it is important to ensure chemical compatibility, particularly for gaseous applications.

Fittings for Different Industry Applications

Hydraulic hose fittings are used in a number of different industries, including mining, agriculture, and offshore operations.

It is important that you select the right fittings for your industry and use.

Contact Gerrard Hydraulics for Custom Fitting Solutions

Choosing the right hydraulic hose fittings for your system will help keep your system safe and operating at optimal levels.

Professional expertise and tailored advice take the stress out of choosing the right fittings and help ensure a safe, efficient hydraulic system.

Gerrard Hydraulics are Perth’s trusted hydraulic hose and fittings suppliers.

Our experienced staff and technicians can provide custom fitting recommendations and services for your business, helping ensure you get the right fittings for your job.

Contact us today for reliable expert advice.